LCMS-8060NX

INDUSTRY

Environment

KEYWORD

CO2, carbon neutral, Kyushu University

INTRODUCTION SERVICE&PRODUCTS

LCMS-8060NX, GPC System, TOC-L Series, CFT-EX Series, AT Series

What comes to mind when you hear the words "environmental issues"? I think many of you will think of the "climate change problem," which is affecting our daily lives due to rising temperatures, changing ocean temperatures, heavy rainfall and more intense typhoons / cyclones / hurricanes. Some may think of the "waste plastic problem," which is caused by single-use plastics, as represented by charging for plastic shopping bags and substituting plastic straws for paper ones.

We spoke with Associate Professor Taniguchi of the International Institute for Carbon-Neutral Energy Research at Kyushu University, who is working on research to solve these two important environmental problems.

Associate Professor Taniguchi of the International Institute for Carbon-Neutral Energy Research at Kyushu University, who is working on research to solve environmental problems.

*Affiliates and titles of the interviewee are current as of the time of reporting.

International Institute for Carbon-Neutral Energy Research, Kyushu University

My specialty is polymer chemistry. When I was at the Kyoto Institute of Technology, I worked as an assistant professor in the laboratory of Professor Emeritus Yoshiharu Kimura to study polylactic acid (PLA), a biodegradable polymer derived from plants. Since then, I have been using Shimadzu's analytical instruments (Differential Scanning Calorimeter (DSC), Liquid Chromatograph-Mass Spectrometer (LC-MS), Scanning Probe Microscope (SPM), etc.). Currently, we are developing plastics made from CO2 and biomass materials that can be recycled multiple times and will decompose in the natural environment. The plastics under development have three features that are good for the environment. First, they can be processed under pressure at near room temperature, which reduces the energy consumption during the molding process and, thus, reduces CO2 emissions. Second, because they are made from CO2 and biomass materials, it addresses the problem of oil depletion. Third, unlike conventional plastics, they can be molded without heating, meaning that they are not pyrolyzed, making them infinitely recyclable. Conventional plastics degrade due to thermal decomposition during material recycling, but the plastics we are currently developing are expected to become next-generation plastics that can be readily recycled. In our research and development project, Shimadzu's flow tester is used to evaluate the low-temperature flow of the plastics, and a gel permeation chromatography (GPC) system is used to measure their molecular weights. In addition, we are developing CO2 capture and utilization technology that selectively separates CO2 contained in the exhaust gas from thermal power plants. I have been conducting this research on the issue of CO2 since joining the Research Institute of Innovative Technology for the Earth (RITE). How to use the separated CO2 is essential to realize the goal of achieving a carbon-neutral society by 2050. Currently, we are conducting research to convert the separated and recovered CO2 into raw materials for plastics and cement, as I mentioned earlier.

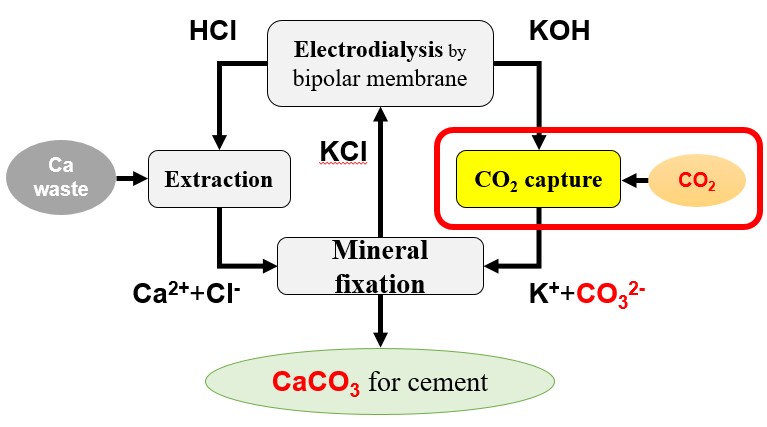

Scheme for Efficiently Producing Calcium Carbonate from CO2 in Exhaust Gas

Currently, we are working with industry and academia to develop technology to recycle CO2 emitted from cement plants, with the aim of implementing it in society by 2030. The cement industry is the third-largest source of CO2 emissions in Japan after thermal power plants and steelworks. To address this, we are conducting research into reducing emissions and using CO2 effectively in cement production.

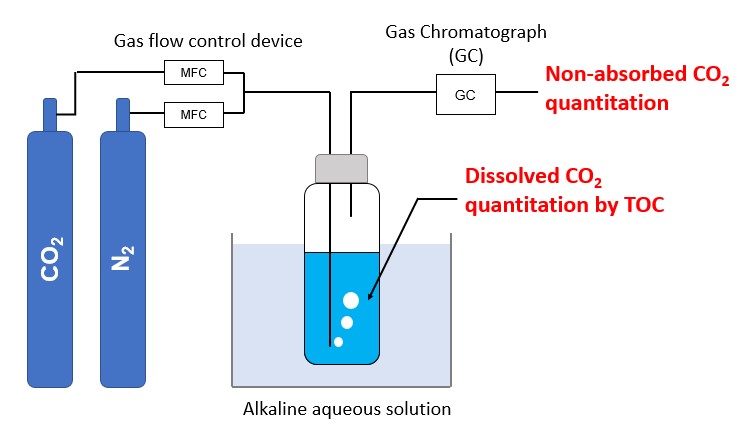

In this project, CO2 generated during the production of cement is separated as carbonate ions in an aqueous solution and combined with Ca2+ extracted from Ca-containing waste to form calcium carbonate. This is then used again as a raw material for cement. In the conventional CO2 capture process, which uses an alkaline aqueous solution, an enormous amount of energy is required when the separated CO2 is recovered from the aqueous solution by heating. In our process, CO2 is used directly without being recovered, so very little energy is required. The process is also characterized by its high recovery efficiency and rate. Shimadzu's Gas Chromatograph (GC) is used to determine the separation efficiency of CO2 in the exhaust gas, and a Total Organic Carbon (TOC) analyzer is used to determine CO2 in solution. We are now preparing a pilot demonstration of the technology.

Carbon dioxide separation experimental apparatus

Total Organic Carbon (TOC) Analyzer

Shimadzu Corporation’s analysis instruments are easy to use and highly reliable, and I have been using them since I was a student. I think the exterior design has improved recently. I am also satisfied with the support system, and I have visited Sanjo Works many times for demonstration analyses. The current flow tester is indispensable for our research on biodegradable plastics that can be pressure-molded at room temperature. The working temperature is above room temperature, but if we could cool it down, the scope of our research would expand. It would also be helpful if pressure up to 100 MPa could be applied. Future demands include the development of portable gas chromatographs that can be used for on-site gas analysis at various CO2 emission sources. TOC analyzers and gas chromatographs are very useful for the research and development of CO2 capture technology, and I would like to extend the research and development to carbon neutral and then to carbon negative outcomes.

Shimadzu Gas Chromatograph (GC-2014), Total Organic Carbon Analyzer (TOC-L) + Autosampler, Liquid Chromatograph (LC-20 series), Flow Tester (CFT-500EX), and Electronic Balance (ATX324) are used in the laboratory. Shimadzu will continue to develop products to help make further contributions. Thank you very much for your extremely valuable talk today.